1. The Importance of Dust Control in Cleanrooms

Dust control is a crucial factor in maintaining a sterile environment in cleanrooms where sensitive products and equipment are manufactured. Even ultra-fine particles, invisible to the naked eye, can seriously affect product quality, cause contamination, and compromise the safety of production processes. In the manufacturing of high-precision devices such as semiconductor chips, displays, sensors, and sterile pharmaceuticals, the presence of particles as small as 0.3 μm – 5 μm can result in severe product defects.

Some key reasons why dust control in cleanrooms is essential include:

-

Preventing product and environmental contamination: Dust particles can carry microorganisms and chemical contaminants that settle on product surfaces, equipment, or wafers/silicon, directly impacting performance and output reliability.

-

Maintaining cleanliness to international standards: A Class 100 (ISO 5) cleanroom requires particle density ≤ 3,520 particles/m³ (0.5 μm size) and ≤ 10,200 particles/m³ (0.3 μm size). Therefore, real-time particle density monitoring is necessary to control HVAC, AHU, FFU, and unidirectional airflow systems.

-

Protecting the quality of sensitive products: Products such as pharmaceuticals, microchips, medical devices, and high-tech items must be produced in dust-free environments. A particle control system ensures that these products are not damaged or contaminated by airborne particles.

-

Safeguarding worker health: Airborne dust can cause health issues for workers, especially fine particles that can enter the respiratory tract. Dust control ensures a safe working environment and protects employee health.

2. Particle Counters and ESD Control Systems

2.1. Particle Counters

INDEX Technology Co., Ltd provides comprehensive cleanroom dust control solutions, from system design and installation to maintenance. We apply advanced technologies and modern equipment to help businesses monitor and maintain cleanroom environments that meet international standards, preventing the intrusion and spread of airborne particles.

Particle counter

| Specification | Value |

|---|---|

| Dust Particle Detection Principle | Laser light scattering principle |

| Number of Channels | Multi-channel (0.3 μm, 0.5 μm, 1.0 μm, 5.0 μm, 10 μm) |

| Counting Efficiency | 50% @ 0.3 μm; 100% @ 0.5 μm (252 ± 50, 10%RH environment) |

| Measurement Range | 0 ~ 1,000,000 particles / 28.3 L |

| Stabilization Time After Power-On | ≤ 8 seconds |

| Data Update Rate | 1 second |

| Operating Temperature / Humidity | 0 ~ 45°C; 0 ~ 95%RH (non-condensing) |

| Storage Conditions | -20 ~ 60°C; 0 ~ 95%RH (non-condensing) |

| Operating Voltage | DC 24.0V ±15% |

| Average Current Consumption | ≤ 3A |

| Communication Interface | RS485 interface (standard), RJ45 port (standard) |

| Product Lifespan | Over 3 years |

| Sampling Flow Rate | 28.3 L/min |

| Sampling Probe | Constant flow rate sampling probe |

| External Sampling Port | Inner diameter: φ10 mm |

| Operating Mode | Adjustable (default: work 2 minutes / pause 28 minutes) |

| Display Screen | 3.5-inch screen |

| Calibration Standard | JJF 1190-2008 |

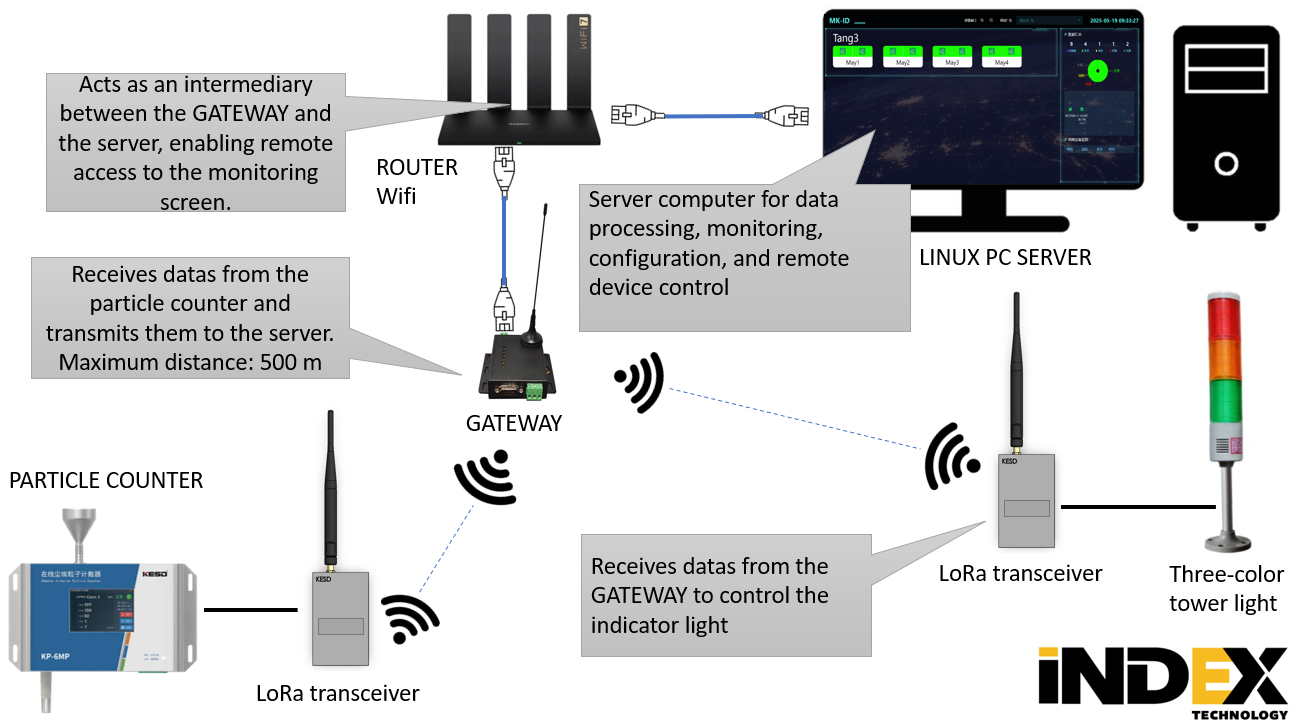

2.2. Particle Control System

INDEX Technology Co., Ltd provides automated dust monitoring systems that continuously track airborne particle concentration in cleanroom environments. This system delivers real-time data and issues alerts when particle levels exceed permissible limits, enabling businesses to make timely adjustments and maintain compliance with cleanliness standards.

-

Real-time monitoring: Our dust monitoring system operates 24/7, providing detailed information on airborne particle concentrations in the cleanroom. This allows businesses to easily track and adjust environmental conditions as needed.

-

Automatic alerts: When particle concentrations exceed safety thresholds, the system automatically issues alerts via email, indicator lights, and display screens, allowing managers to respond promptly and prevent the risk of cleanroom air contamination.

-

Data reporting and analysis: INDEX Technology’s dust monitoring system generates detailed particle concentration reports over time, helping businesses analyze and optimize dust control processes to ensure maximum production efficiency.

-

Data storage: The system supports data storage on server computers, SQL databases, and data export in Excel format.

-

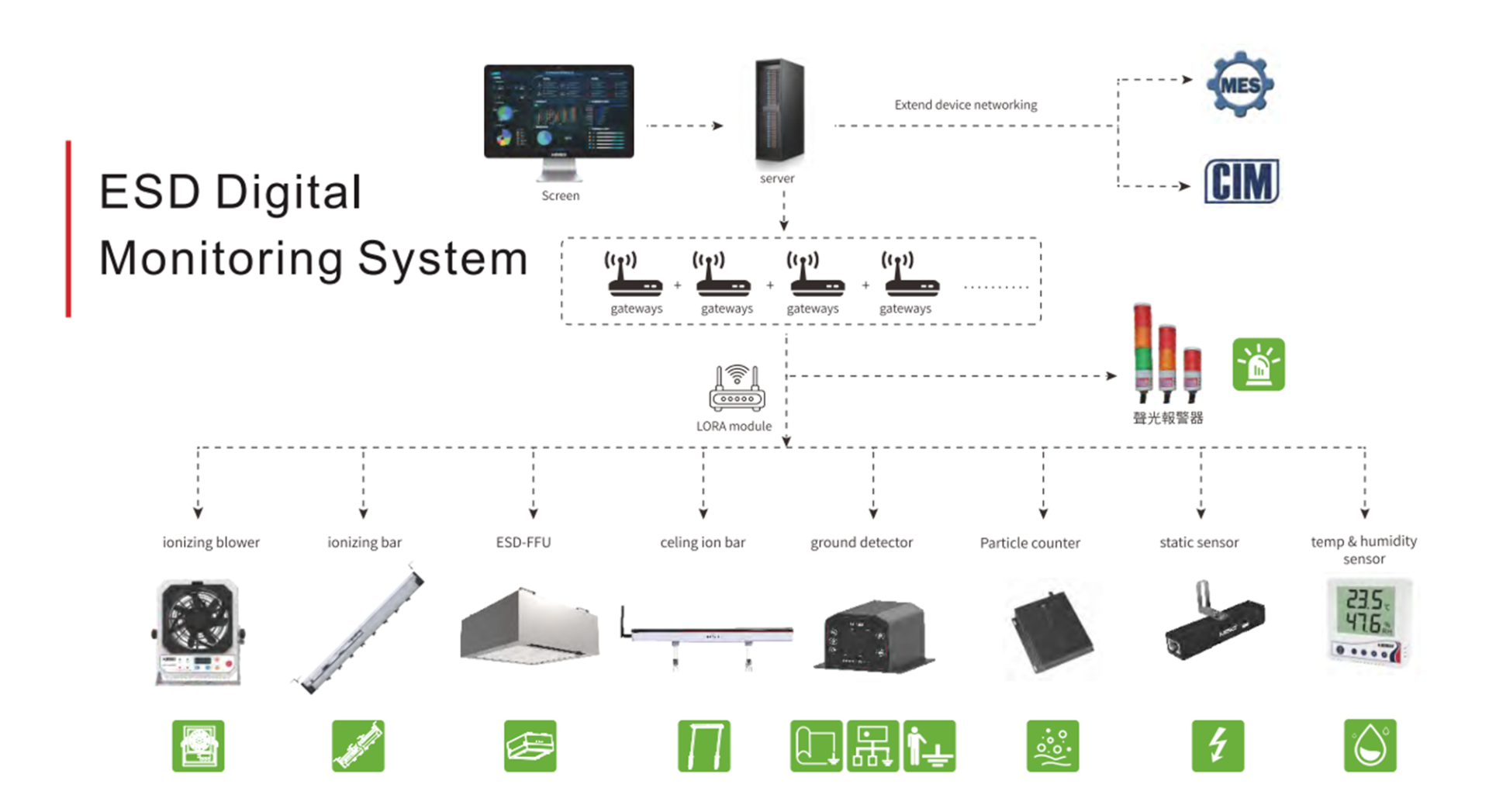

System expansion: The system supports integration with a variety of cleanroom devices, including ionizers, electrostatic sensors, temperature sensors, and humidity sensors.

3. Benefits of the System

Using the cleanroom particle control system from INDEX Technology Co., Ltd brings numerous practical benefits to manufacturing and research enterprises:

-

Ensuring a sterile and safe environment: The particle control system removes airborne dust and bacteria, ensuring the cleanroom environment consistently maintains sterility and safety for production processes.

-

Protecting product quality: Strict control of airborne dust levels helps safeguard product quality, prevent contamination-related issues, and ensure products meet the highest standards.

-

Reducing operating costs: The system is optimized for energy efficiency, helping businesses minimize operating and maintenance costs while maintaining maximum operational effectiveness.

4. Comprehensive Consulting and Support Services from INDEX

INDEX Technology Co., Ltd not only provides cleanroom particle control solutions but also delivers comprehensive consulting and support services. Our team of engineers and experts is always ready to advise, design, install, and maintain dust control systems for clients, ensuring compliance with the specific requirements and standards of each industry.

Conclusion

INDEX Technology Co., Ltd is proud to be a trusted partner in delivering cleanroom particle control solutions that meet international standards. With an experienced team of experts and advanced technology, we are committed to providing customers with the most optimal solutions, helping maintain a sterile, safe, and efficient cleanroom environment. INDEX is always ready to accompany businesses in building and developing cleanroom systems, contributing to the success and sustainable growth of our clients.